In this blog, we will delve into an essential guide to understanding and operating an air compressor. Air compressors are versatile tools, widely used in industries and homes for a variety of applications such as inflating tires, powering pneumatic tools, painting, cleaning, and that’s just to name a few.

However, despite their widespread utility, many individuals often struggle with the correct operation and required maintenance of these systems. Mistakes can lead to inefficient operations, increased costs, or even potential safety hazards. As such, it’s crucial to learn how to use an air compressor correctly.

It is also important to keep in mind what issues are most common in air compressors. To better understand these issues, read our previous blog where we went in-depth discussing problems frequently encountered in air compressors.

This blog post serves as a comprehensive guide to give you the knowledge and confidence you need to use an air compressor effectively. Whether you’re a beginner tackling your first project or an experienced hand looking for a refresher, this article has got you covered. We’ll start from the basics, work through a step-by-step guide, provide maintenance and safety tips, and explore practical applications of air compressors. Here’s how Advanced Air & Vacuum can help you make the most out of your compressor. Let’s dive right in.

Understanding the Basics of an Air Compressor

Before we delve into the practicalities, let’s first establish a solid ground of understanding – what is an air compressor and how does it function? An air compressor is a powerful device that converts power into potential energy stored in compressed air. It works by sucking in a large amount of air, compressing it, and storing it under pressure in a tank. This stored high-pressure air is then released in a controlled manner to power a variety of tools and applications.

Let’s Familiarize Ourselves with a Few Key Terms:

- Compressed Air: This is air that is kept under a certain amount of pressure, typically greater than atmospheric pressure, ready to be used when needed.

- PSI (Pounds per Square Inch): This is the unit used to measure air pressure in the compressor tank.

- Cubic Feet: In the context of air compressors, this refers to the volume of air moved by the compressor per minute.

There are Various Types of Air Compressors, Each Suited for Specific Tasks:

- Portable Air Compressor: This is compact and mobile, great for home use or mobile operations like roadside tire inflation.

- Electric Air Compressor: Uses an electric motor to drive the compressor, is quiet, and generally requires less maintenance. They’re ideal for indoor operations.

- Industrial Air Compressor: Used in factories and industrial environments, these beasts can deliver high power for large scale applications.

- Gas-Powered Air Compressor: Powered by gasoline, these machines are typically robust and perfect for outdoor projects where electricity may not be readily accessible.

Understanding the details of your air compressor, from type to capacity, will help you get the best performance in every task. In the next section, we’ll guide you through the steps of using an air compressor in a practical way.

Step-by-Step Guide on Using Air Compressors

Now that we’ve established the basics, it’s time to understand how to use your air compressor correctly. The first crucial step is to read the owner’s manual. No matter what type of compressor you own, the manufacturer’s guidelines will hold specific insights about the model you are using.

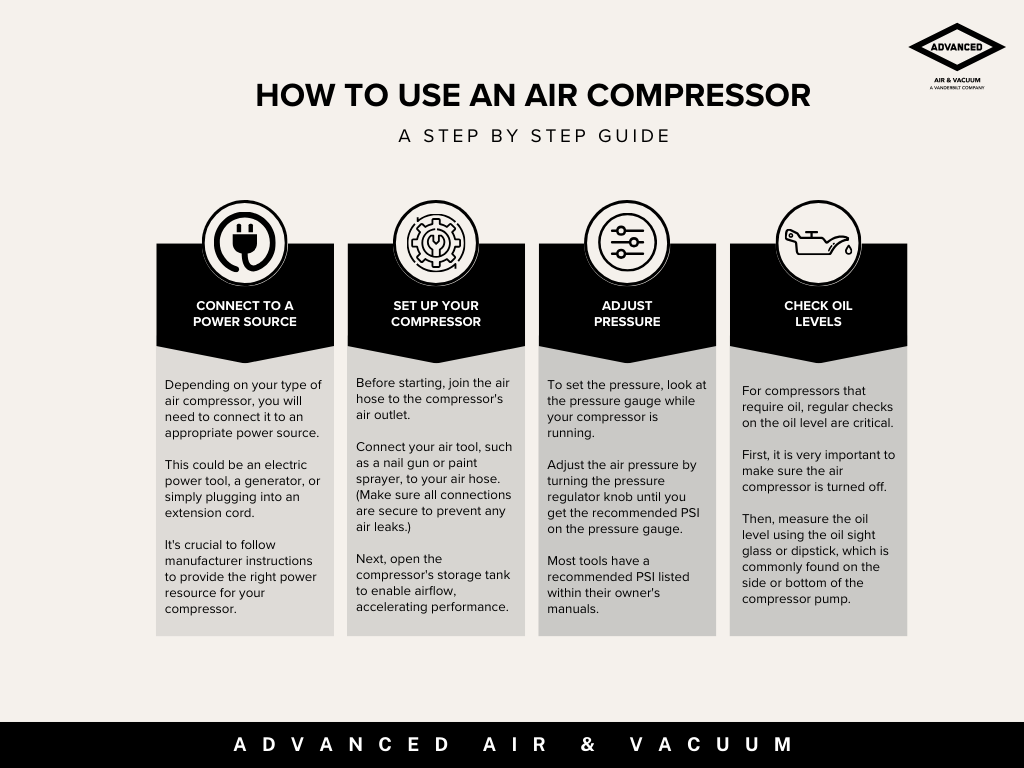

- Connecting your compressor to a power source: Depending on your type of air compressor, you will need to connect it to an appropriate power source. This could be an electric power tool, a generator, or simply plugging into an extension cord. It’s crucial to follow manufacturer instructions to provide the right power resource for your compressor.

- Setting up your compressor: Before starting, join the air hose to the compressor’s air outlet. Connect your air tool, such as a nail gun or paint sprayer, to your air hose. Make sure all connections are secure to prevent any air leaks. Next, open the compressor’s storage tank to enable airflow, accelerating the compressor’s performance.

- Adjusting pressure: Your pneumatic tools will need distinct pressure levels (PSIs) to operate optimally. To set the pressure, look at the pressure gauge while your compressor is running. Adjust the air pressure by turning the pressure regulator knob until you get the recommended PSI on the pressure gauge. Most tools have a recommended PSI listed within their owner’s manuals.

- Checking Oil Levels: For compressors that require oil, regular checks on the oil level are critical. To check the oil level on an air compressor, locate the oil sight glass or dipstick, which is commonly found on the side or bottom of the compressor pump. Always make sure the compressor is turned off and fully depressurized before performing any maintenance. Using the compressor with inadequate oil can significantly harm the electric motor.

So far, so good? Remember, every air compressor might have its specifics, but the basic operation remains the same. In the next section, we’ll identify key maintenance steps and safety precautions to ensure the longevity of your device and your own well-being.

Maintenance and Safety Tips

A well-maintained air compressor is a long-lasting one. But more critically, proper maintenance ensures safer operation. So, let’s discuss some essential maintenance and safety measures.

Regular Checks

Scheduling regular checks can prevent potential problems that could lead to system breakdowns. Key components to inspect include the air filter, oil level (for oil-lubricated compressors), air compressor tank, and drain valve. The aim is to ensure all these components are in good shape and replace any worn-out parts promptly.

Proper Draining of the Compressor Tank

Moisture tends to accumulate in the air compressor tank over time, especially in a humid environment. This can lead to rust and damage to the tank. To avoid this, drain your air compressor tank regularly. Most tanks come equipped with a drain valve at the bottom. It’s essential to always have the air release before you drain the water.

Safety First

Always wear proper safety gear when operating your compressor, including safety glasses and steel-toe boots. Make sure to keep the work environment clean and free of clutter to avoid accidents.

Consider the Air Hose

The air hose is one of the unsung heroes when operating an air compressor. Make sure the hose is properly connected and in good condition. If the air hose is damaged, it could lead to the hose bursting, causing severe injuries.Preventative maintenance increases the lifespan of your compressor and keeps it functioning effectively. In the final section, we will explore the various practical applications of air compressors. Let’s make the most out of your air compressor!

Practical Applications of Air Compressors

Air compressors are incredibly versatile devices with countless practical applications. Apart from powering your pneumatic tools effectively and efficiently, air compressors can make a surprising number of everyday tasks much simpler. Let’s consider a few:

- Inflating Tires: Whether it’s a bike tire or a motorbike tire, you would find your air compressor very handy. They allow you to set your desired PSI, ensuring safety and optimal performance.

- Cleaning: By generating a strong gust of air, compressors can be used for speedy and effective cleaning. This could range from sandblasting your power tools and workspaces to powering a car wash.

- Torque Wrench Operations: In auto repair shops and garages, air compressors are often used to generate the high torque output required for various tasks such as removing lug nuts from tires.

- Gas Station Applications: At the gas station, a reliable air compressor is used to inflate car tires and sometimes even balance them.

- Advanced Applications: It’s not just about inflating tires or cleaning dust. When you have a bigger compressor, you can take on heavy-duty tasks like operating jackhammers, powering high-scale paint sprayers, or even complex machinery in large industrial settings.

Knowing how to use an air compressor can simplify many tasks, making your life easier. It’s not just about the utility; with every puff of compressed air, you’re saving time, effort, and money, and therefore improving your work’s efficiency. It’s all about understanding what this efficient tool is capable of.

These are just a few examples – but the potential uses for a compressor in your home or business are numerous. Check out our Industries & Applications pages for more practical uses for air compressors.

Now that you have a clearer understanding and confidence to take on air compressor tasks, ensure you maintain your device well and stay safe.

Advanced Air & Vacuum: Serving All Your Compressed Air Needs

Advanced Air & Vacuum is your trusted partner for all your compressed air needs. We take pride in delivering top-tier air equipment and providing unrivaled servicing to keep your systems running smoothly. Through our extensive range of products and services, we strive to make your compressed air system more efficient and effective.

At Advanced Air & Vacuum, we are committed to finding you the right air compressor for your needs. Contact us today for a recommendation for what air compressor to buy for your specific needs. We also offer the service of installing whichever air compressor you choose.

We also provide other compressed air products and services. We do pump repairs, removal, and installation. We are the exclusive authorized dealer of Prevost Aluminum Air Piping products. Additionally, we provide industrial vacuum pump & motor rewinding sales and service. Request a quote now!