Industrial AiR Compressors for

SANDBLASTING

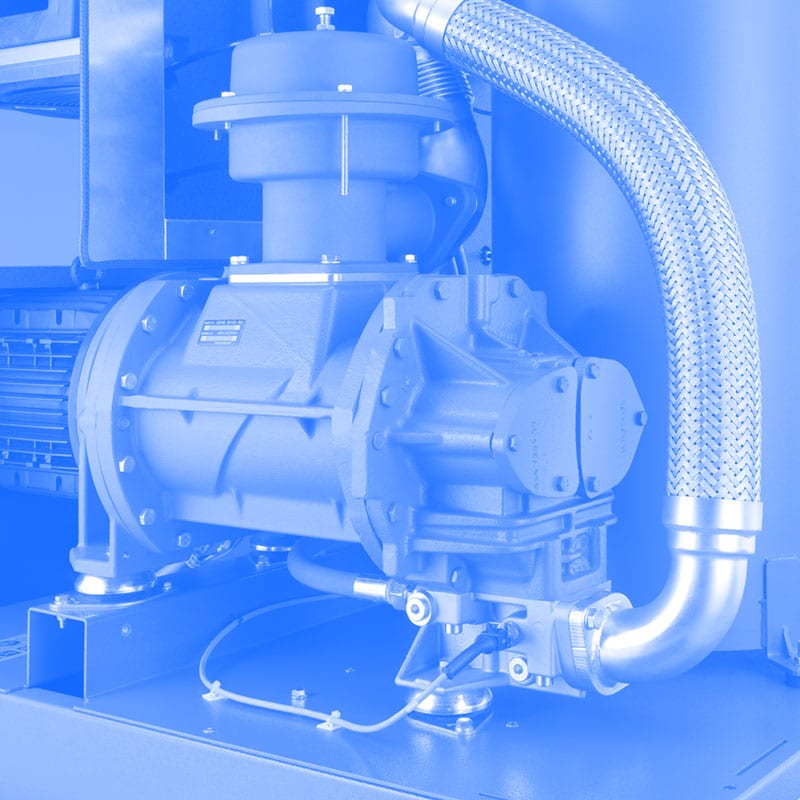

At Advanced Air and Vacuum, we offer a wide range of industrial air compressors designed for sandblasting amd media blasting applications. Whether you’re a professional sandblasting contractor or a hobbyist looking to tackle some DIY projects, our selection of air compressors provides the power and reliability you need to get the job done efficiently and effectively.

Commitment to Excellence

Advanced Air & Vacuum is the premier provider of air compressors for sandblasting. Our dedication to customer satisfaction and range of product and service offerings set us apart as the best option for all your air system needs, including sales, rentals, installation, maintenance, and repair.

Expertise in Action

Our EASA-certified service technicians have extensive knowledge in managing and handling air compressors designed for sandblasting, covering nearly every recognizable models and brands on the market. This knowledge enables us to address various compressor needs, ensuring your sandblasting equipment operates at its best.

Applications and Uses

Air compressors generate a high-pressure airflow required to propel abrasive materials like sand, glass beads, or aluminum oxide at a high velocity against a surface. This process effectively removes coatings, rust, or other unwanted materials and can be used across a range of applications.

1. SURFACE PREPARATION FOR PAINTING

Commonly used in industrial painting applications, sandblasting is used to remove old paint, rust, and other contaminants before applying new coatings.

2. CLEANING AND RESTORATION OF CONCRETE SURFACES

Sandblasting can be used to clean and restore concrete surfaces such as sidewalks, bridges, and parking garages.

3. CLEANING OF METAL PARTS AND EQUIPMENT

In industrial settings, sandblasting is routinely used to clean metal parts and equipment, ensuring they are free from debris and ready for use.

4. MANUFACTURING AND METAL FABRICATION

Within the manufacturing and metal fabrication industries, sandblasting is commonly used to prepare metal surfaces for welding or other joining techniques.

5. REMOVAL OF GRAFFITI

Sandblasting can be an effective method for removing graffiti from concrete, brick, or stone surfaces.

Which Air Compressor Do I Need for Sandblasting?

It’s important to have the right air compressor when sandblasting because the required airflow, pressure, and volume can vary depending on the size and complexity of the job. Whether you’re undertaking larger industrial applications or smaller sandblasting tasks, each demands specific compressor capabilities to ensure the best performance and results.

Air Flow

The air flow rate, measured in cubic feet per minute (CFM), is a critical factor in determining the industrial air compressor you need for sandblasting. The CFM requirements for sandblasting will vary depending on the nozzle size you use. For example, a larger nozzle will require a higher air flow, which means you’ll need a bigger compressor to provide enough CFM.

Pressure

The air pressure of a compressor, measured in pounds per square inch (PSI), is crucial for determining the effectiveness of an air compressor for sandblasting. Most sandblasting equipment require a minimum air pressure of 90 or 100 PSI to operate effectively, however, the required PSI will vary depending on the specific sandblasting task and the hardness of the surface being treated.

Tank Size

In general, it’s better to get a larger tank because it has a larger air volume so it will provide more consistent air flow and improve the duty cycle, allowing the compressor to cycle less frequently, reducing wear and tear on the compressor motor. This enhances the longevity of the compressor and improves its operational efficiency.

Deciding on the right air compressor for your sandblasting needs can be challenging without extensive experience and knowledge of the requirements for different tasks. So, if you need assistance, feel free to contact us or give us a call. Our team is more than happy to provide the expertise and support you need to make an informed decision.

Our Process

- Contact Us:

Begin your service by getting in touch with us. Whether you're looking to install, rent, or get routine maintenance on an air compressor, fill out our form or call for a direct consultation. - Diagnosis:

Using advanced diagnostic tools and an understanding of air compressor mechanics, we conduct a thorough assessment to ensure you're provided with a solution that meets your specific needs. - Service:

Depending on your needs, our service technicians will install, replace, or perform maintenance, focusing on reducing downtime and ensuring your compressor adheres to the highest safety and performance standards. - Leave a Review:

Your feedback is important to us. We encourage you to leave a review to help us continuously improve the quality of our services.

Choose Advanced Air & Vacuum Today!

Don’t let compressor issues impede your sandblasting projects. Contact Advanced Air & Vacuum today to discuss new compressor options, and schedule an installation, inspection, replacement, repair, or maintenance service. Specializing in solutions tailored for sandblasting applications, we are dedicated to ensuring you have an air compressor that provides the best sandblasting results.

Fill out a form or call us to explore how we can support your needs.