ADVANCED AIR & VACUUM'S AIR COMPRESSOR MOTOR REPLACEMENT SERVICE

At Advanced Air & Vacuum, we understand the critical role air compressors play, from operating heavy-duty machines in industrial environments to powering pneumatic tools at home workshops. Our air compressor motor replacement service is meticulously designed to restore your old compressor’s functionality to its peak, ensuring efficiency, minimizing operational interruptions, and extending its lifespan.

Commitment to Excellence

Advanced Air & Vacuum is the premier provider of solutions for air compressors, vacuum pumps, and associated machinery. Our dedication to customer satisfaction and range of product offerings distinguish us as your preferred partner for all air system needs, including sales, installation, maintenance, removal, and repair.

Expertise in Action

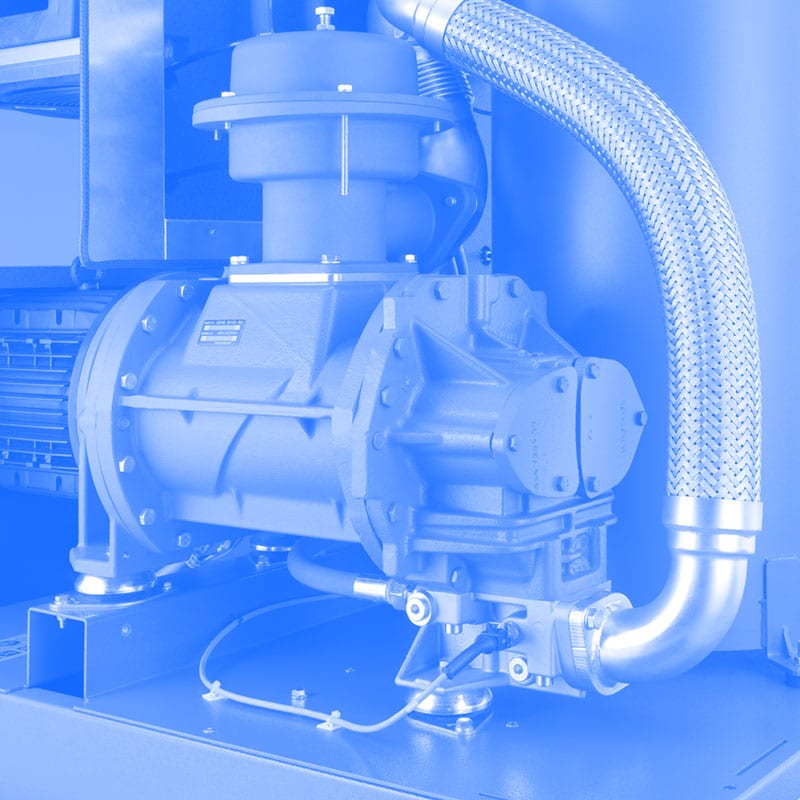

Our team possesses extensive expertise in dealing with nearly every air compressor motor, model, and brand on the market, including single-phase motors, electric motors, HP compressors, portable compressors, industrial compressors, oil-less compressors, and more. This knowledge allows us to tackle any motor replacement or maintenance requirement, from routine inspections to intricate motor repairs, ensuring your equipment operates efficiently and reliably.

Identifying Common Lift Issues

Air compressor motors can experience a range of problems, such as overheating, electrical faults, and wear due to prolonged use. Identifying these issues early is vital to avoiding extended downtime. Some common motor issues include:

- Overheating

- Excessive Noise or Vibration

- Failure to start

- Frequent thermal overload tripping

- Reduced compression efficiency

- Electrical burning smell

- Inconsistent motor speed

- Excessive Oil Consumption

Early detection of these signs can lead to expedited, more effective replacements, saving you time and resources.

Our Motor Replacement Process

- Contact Us:

Initiate your service by getting in touch with us. Fill out our online form or call today for a direct consultation with our experts. - Diagnosis:

Leveraging advanced diagnostic instruments and an understanding of air compressor mechanics, we conduct a thorough evaluation to pinpoint the cause(s) of your compressor's issues. - Repair:

Our EASA-certified technicians undertake the motor replacement or necessary maintenance, focusing on reducing downtime and ensuring your compressor adheres to the highest safety and performance standards. - Leave a Review:

Your feedback is invaluable to us and aids in our ongoing effort to refine our services. We encourage you to leave a review to help us enhance our service quality.

Choose Advanced Air & Vacuum Today!

Avoid Unexpected Downtime

To prevent unexpected system failures that could lead to costly downtimes or necessitate a complete replacement air compressor, it’s essential to engage in timely maintenance and motor replacements. Routine checks play a pivotal role in identifying and addressing potential issues early on, enhancing the longevity and reliability of your compressor system.

Enhance Efficiency

Regular maintenance is imperative for uninterrupted operations. Timely servicing on a motor, old or new, enhances efficiency by minimizing operational halts and maintaining your air compressor’s peak performance.

Reduce Energy Costs

An efficiently running compressor consumes less energy, saving you money in the long-term on operating costs. By ensuring that your air compressor is maintained regularly, you can achieve significant energy savings, lowering your energy expenses over time.

.

Get in Touch

Don’t let compressor motor issues get in the way of your productivity. Contact Advanced Air & Vacuum today to schedule your air compressor inspection, motor replacement, or maintenance service. Whether you’re in an industrial setting, a commercial application, or managing a home workshop, we’re here to ensure your air compressor is in optimal condition. Fill out our form or call us to find out how we can meet your air compressor needs.

Additionally, if you’re looking for new compressor options, installations, or preventive maintenance and repairs? We offer an extensive range of equipment and services tailored to meet your specific needs!