Automotive Equipment Division

Welcome to our Automotive Equipment Division – your go-to destination for top-notch industrial air compressors and expert automotive equipment services. Whether you run an automotive repair shop or manage an automotive dealership, we’ve got you covered. Our knowledgeable team is committed to providing quality service in a timely manner with minimal downtime ensuring your equipment is reliable and safe. As an ALI-certified lift inspection company, we specialize in lift inspections, installations, maintenance, and repairs. We are also involved in providing you with tire changer, wheel balancer, oil pump, oil systems, air reels, water reels, and oil reel repair, replacement and installation. We specialize in installing air lines, oil lines and water lines from a one-bay shop to a complete dealership system. Explore how our industrial air compressors can elevate your shop’s performance.

Two-Post Lifts

In a two-post lift, lift arms are affixed to a carriage that smoothly ascends and descends in two vertical columns. Most two-post lifts rely on a hydraulic pump that pressurizes cylinders, push the carriage to the desired height. The equalizing cables help in lifting both carriages in a level position. It is very critical that the safety locks are operating correctly.

Explore our lift options for an efficient and reliable auto-lift solution.

Four-Post Lifts

Contrasting the two-post lift, four-post lifts feature runways, which your vehicle’s wheels drive on, connected to four vertical posts – two at the front and two at the rear. A hydraulic pump activates a piston linked to a cable system. This cable system, in turn, raises the runways, raising your vehicle securely. Most lifts contain a safety lock, found on each post, which is released with compressed air, courtesy of our air compressors.

Discover our range of equipment company solutions for an optimal truck lift experience and explore versatile vehicle lift options.

Alignment Racks:

Efficient Wheel Service

Our industrial air compressors power alignment racks by supplying essential compressed air to operate the hydraulic system within the rack. This hydraulic system facilitates adjustments needed for aligning a vehicle’s wheels. Pneumatic cylinders, connected to a control valve, allow precise positioning of wheel clamps and alignment sensors. A continuous supply of compressed air from the air compressor ensures seamless operation during automotive lift inspection or routine maintenance, making it an indispensable tool for any auto shop.

Balancers:

Precision in Heavy Duty Lifts

Utilize AAV’s industrial air compressors for dynamic balancing in heavy-duty lifts. Paired with wheel balancers, our compressors facilitate dynamic balancing, optimizing the performance of rotating objects like wheels, shafts, and turbines. Compressed air suspends the object in mid-air, enabling it to spin freely for accurate measurements. The compressor’s adjustable pressure also aids in adding or removing weight as needed. Enhance your shop equipment with this dynamic balancing solution for efficient and vibration-free heavy-duty post lifts.

Hose Reels:

Streamlined Shop Efficiency

AAV’s industrial air compressors power automotive hose reels, ensuring streamlined shop efficiency. Connected to the compressor via an air hose, these reels release compressed air to drive the reel mechanism when needed. The pneumatic motor or cylinder, powered by the compressor, effortlessly winds or unwinds the hose, offering convenience during tasks. Additionally, the compressed air assists in cleaning and preparing hoses for storage, maintaining their readiness for future use. Elevate your auto shop efficiency with this reliable combination of air compressors and hose reels.

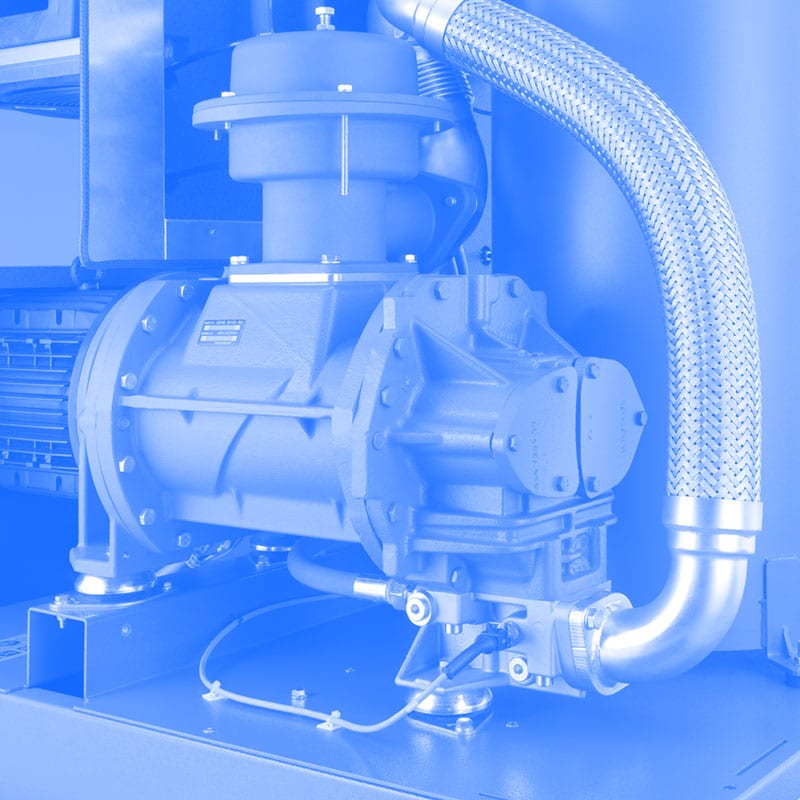

Enhancing Your Automotive Equipment with Advanced Air & Vacuum

In the dynamic automotive industry, ensuring your air compressor meets the highest standards is crucial for smooth operations. At Advanced Air & Vacuum, we bring years of experience and professional service to cater to all your air compressor needs. Here’s how we contribute to your compressed air journey:

Comprehensive Services:

- Proactive Maintenance:

From changing filters to monitoring lubrication, our maintenance services cover all aspects, ensuring longevity and optimal functionality. - Thorough Inspection:

Our experienced technicians conduct meticulous inspections, identifying potential issues to maintain peak performance and minimize downtime. - Expert Installation:

Our certified technicians offer professional installation, tailoring the setup to your specific needs within the automotive industry. - Responsive Repairs:

Advanced Air & Vacuum delivers quick, effective solutions with quality products and expert service in the automotive industry, ensuring customer satisfaction and operational enhancement.

Explore our range, from gas engine compressors to portable Quincy options, ensuring a perfect fit for your workshop. Additional components like refrigerated air dryers enhance efficiency and reduce system contaminants