Welcome to our in-depth comparison of two important pieces in the world of compressed air—air pumps and air compressors.In this blog, we will explore the similarities, differences, and various applications of air pumps and air compressors. So whether you’re an engineer, a DIY enthusiast, or someone who is simply curious about air systems, stay with us as we venture into the realm of air pumps and air compressors. The purpose of this article is to empower you with knowledge, guiding you toward informed decisions when it comes to your air system needs.

Understanding Air Pumps

To start, let’s begin our analysis by better understanding air pumps. Air pumps present a marvel of simplicity and utility, effectively leveraging the straightforward principle of air displacement.An air pump fundamentally does exactly what it says – it pumps air. Sounds simple enough, right? Its primary aim is to pump air into or out of an object or space. An air pump can function either manually by the physical exertion of force or electrically as seen in an electric pump.

Mechanisms Used to Operate Air Pumps

Now, let’s go a bit deeper to understand its intricacies. Air pumps operate by using mechanisms such as a diaphragm pump, foot pump, or as we just mentioned, an electric pump. A diaphragm pump uses a flexible membrane or diaphragm that reciprocates to create a temporary vacuum. This displacement of air creates a change in air pressure, forcing air out on one stroke and drawing air in on the other. A foot pump, on the other hand, has an interface specifically designed for foot operation. Electric pumps represent a more advanced form of air pumps, providing a consistent air supply without the need for manual effort. With portable capacities and a range of sizes to hang out with, electric pumps are often the go-to option for quick and effortless inflation or deflation. In essence, air pumps are the cornerstone of pressurized air handling, offering versatile and accessible solutions to a multitude of inflation or deflation needs. Whether you’re dealing with a flat tire or a deflated air mattress the properly chosen air pump can make a world of difference.

Understanding Air Compressors

As we shift gears from air pumps, we land on the most transformative device in the landscape of air displacement systems – the air compressor. An air compressor plays a pivotal role in our daily lives in ways many of us overlook, from allowing our air conditioners to cool our homes on a hot day, to powering pneumatic tools in factories and workshops around the globe.

What is an Air Compressor?

So, what exactly is an air compressor? To put it simply, an air compressor is a mechanical device that increases the pressure of air by reducing its volume, creating what we commonly refer to as compressed air. To understand this better, imagine a storage tank. The air compressor works by continuously pulling in outside air into this tank, reducing its volume, and creating a reservoir of high-pressure air. This compressed air can then be used as a powerful force to perform various tasks that require more than just natural air pressure. Like air pumps, air compressors have several designs. However, the most common versions are the single-stage and two-stage compressors. The devices are classified based on the number of times that air gets compressed between the initial intake and the final destination.

Single-Stage Air Compressors

Single-stage compressors pull in air and compress it in one motion, generally offering a maximum pressure of about 150 pounds per square inch (psi). These are best suited for tasks that require less air like inflating bike tires, car tires, or operating air tools.

Two-Stage Air Compressors

Contrarily, two-stage compressors have an additional step. Following the initial compression, the air is cooled and then compressed again, generally offering a maximum pressure of about 200 psi. These compressors are often needed for higher capacity applications common in air conditioning, powering high-pressure pneumatic tools, or refrigeration units.

Portable Air Compressors

Of course, understanding these compressors wouldn’t be complete without mentioning portable air compressors. As the name suggests, these compact yet powerful units are designed for on-the-go air supply needs, making them well-suited for quick fixes or inflating items on road trips.Fundamentally, air compressors offer a versatile range of applications from inflating tires to powering an air conditioner or a heat pump, right to operating heavy-duty pneumatic tools at a construction site. The air compressor is an unsung hero in a lot of everyday tasks.

Comparing Air Pump vs. Air Compressor

On the surface, air compressors and air pumps might appear pretty similar – they both work with the displacement of air to create pressure. However, how they achieve their purpose and the applications they serve make all the difference.

Air Pump vs. Air Compressor: Similarities

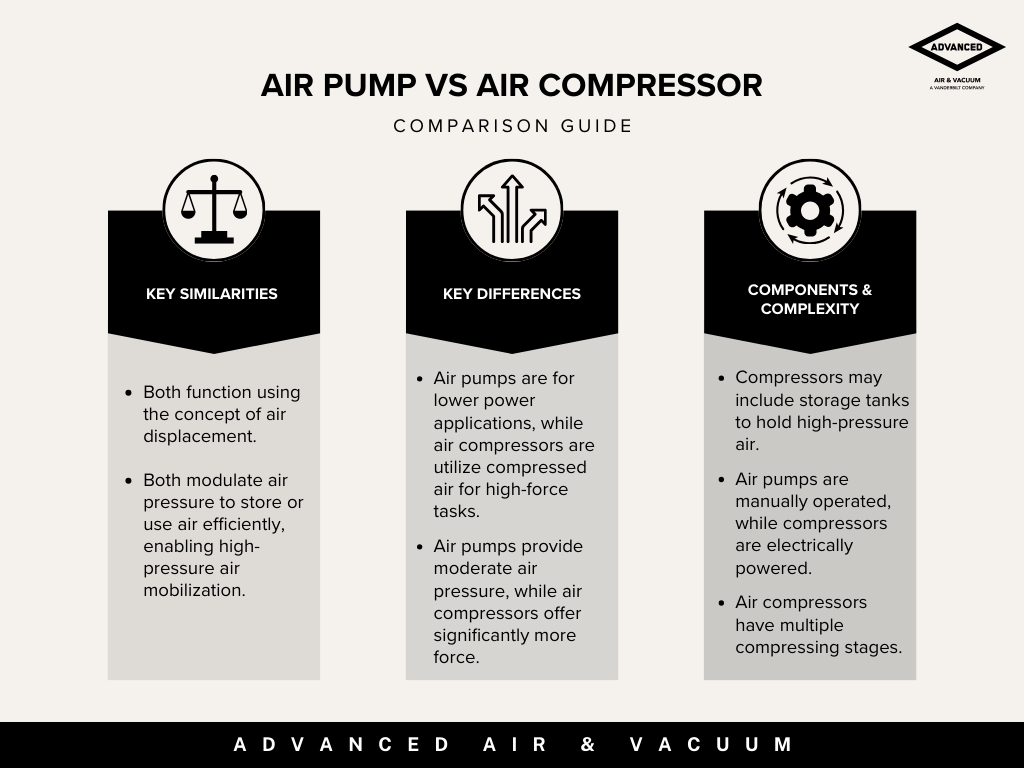

Let’s begin with the similarities. As we mentioned before, both air pumps and air compressors capitalize on the concept of air displacement. They modulate air pressure, creating systems where air can be stored or used. Both air pumps and air compressors provide an efficient way to mobilize high-pressure air.

Air Pump vs. Air Compressor: Differences

The key difference between air compressors and air pumps is in the way they interact with air. An air pump is designed to pump air into or out of a device. It creates air pressure, but not to the point of compressing the air. Air compressors, on the other hand, operate by reducing air volume and creating what is known as compressed air, providing significantly more force.Another differentiator is their capacity and the intensity of the force they can produce. Air pumps are used for situations that need less power like inflating tires or air mattresses where a moderate amount of pressurized air is needed. Air compressors, given their higher capacity, serve applications where more force is required like running pneumatic tools, air conditioners, heat pumps, and more robust machinery.

Air Pump vs. Air Compressor: Components & Complexity

In terms of components, compressors may include storage tanks to hold a reservoir of high-pressure air. This is not typical for air pumps. Also, while air pumps, like bicycle pumps, are predominantly manually operated, air compressors are predominantly powered by electric motors or internal combustion engines.Lastly, air compressors can be a little more complex, comprising of one or more compressing stages, heat exchangers for cooling the air between stages, and more. Conversely, air pumps can be uncomplicated and straightforward.

Applications: Air Pump vs Air Compressor

Now that we’ve established a solid understanding of air pumps and air compressors, it’s time to explore their various applications.

Applications of Air Pumps

- Bicycle Tires: If you’ve ever gone on a bike ride, you’ve likely used an air pump to ensure your tire pressure is at the proper level. These portable tire inflators are invaluable whether you’re dealing with a stubborn Presta valve on your road bike or a Schrader valve on a mountain bike.

- Air Mattresses: Have you ever inflated an air mattress during a camping trip or as an extra bed for guests? Electric air pumps effortlessly inflate these mattresses, providing comfort on the go.

- Inflating Sports Equipment: From soccer balls to basketballs to inflatable pool toys, air pumps are invaluable in keeping recreational equipment ready for use.

- Medical Devices: Certain medical devices, such as nebulizers used for respiratory treatments, rely on air pumps to deliver precise doses of medication in aerosol form.

Applications of Air Compressors

- Pneumatic Tools: Air compressors power a wide range of pneumatic tools, including nail guns, impact wrenches, and sanders, making them essential for construction and woodworking projects.

- Industrial Machinery: In manufacturing and industrial settings, air compressors drive heavy machinery, such as CNC machines and assembly line equipment, ensuring smooth and efficient operations.

- HVAC Systems: Air compressors play a crucial role in promoting air flow for HVAC systems, where they work to supply warm or cool air and regulate humidity.

- Automotive Maintenance: In automotive garages, air compressors are used for tasks like tire inflation, powering air tools for repairs, and operating hydraulic lifts.

- Painting and Woodworking: Professionals in the painting and woodworking industries rely on air compressors to provide a consistent source of compressed air for spray painting and finishing wood.

Understanding these diverse applications allows you to appreciate the versatility of air pumps and the necessity of air compressors. Whether it’s the convenience of an air pump for your bike tires or the power of an air compressor in an industrial setting, these devices are integral to our daily lives.

Choosing the Right Equipment for Your Needs

When choosing between air pumps and air compressors, consider key factors to ensure optimal performance for your specific needs. For air pumps, think about portability, power source, pressure requirements, and required air volume. In contrast, air compressors require considerations like capacity, compressor type (single-stage or two-stage), power source, tank size, and noise level.By carefully evaluating these factors, you’ll be well-equipped to make an informed decision when choosing an air pump or an air compressor. Remember that your choice should align with the specific tasks you intend to perform, whether you need a tire inflator or power for your pneumatic tools.At Advanced Air & Vacuum, we understand that choosing the right equipment can be a daunting task. Our experts are here to guide you through the process, offering tailored solutions to meet your unique air system needs. We’re committed to providing you with top-notch products and services to ensure that your air systems operate at peak performance, enhancing your productivity and efficiency. Remember, at Advanced Air & Vacuum, we serve as your one-stop destination for all your compressed air needs, from air compressor sales and service to Prevost piping.

Sources

- Price Industries. “How Does Displacement Ventilation Work?” Price Industries, 4 May 2021. Web. 29 July 2022.

- Debem. “Operation of Diaphragm Pumps.” Debem, n.d. Web. 29 July 2022.

- IQS Directory. “Industrial Air Compressors.” IQS Directory, n.d. Web. 29 July 2022.

- Air Best Practices. “Pros and Cons of Single-Stage and Two-Stage Rotary Screw Air Compressors.” Air Best Practices, n.d. Web. 29 July 2022.