Air compressors are expensive tools, which is why it is so important to maintain them to ensure their longevity and performance. One simple yet crucial aspect of maintaining your air compressor is regularly draining it. Whether you are dealing with a large industrial air compressor or a smaller compressor, overlooking the importance of draining can lead to a range of problems, from reduced efficiency to significant damage over time. In this blog, we aim to equip you with an easy-to-follow guide on the process of draining your air compressor, making it a task that you can confidently undertake regularly.

An air compressor is a vital tool in various industrial, commercial, and even home settings. It powers everything from pneumatic tools to complex machinery. However, like any piece of equipment, it requires regular care to function at its best. Draining the compressor is not just a recommendation; it’s a necessity. This process helps in removing accumulated moisture, which if left unchecked, can cause corrosion and deterioration of both the compressor and the tools it powers.

So, whether you’re a seasoned professional or new to the world of compressed air systems, this comprehensive guide is designed to provide you with all the information you need to maintain your air compressor effectively.

Why is it Important to Drain Water from your Air Compressor?

The functioning of an air compressor is linked to the concept of air pressure and the use of compressed air. In simple terms, an air compressor takes in atmospheric air and compresses it, resulting in a high-pressure output. This compressed air is a powerful resource, but it comes with an often overlooked byproduct – moisture.

The Basics of Moisture Buildup

When air is compressed, the moisture that was once dispersed in the atmosphere gets concentrated. This is because air can hold less water vapor when it’s under pressure compared to when it’s at atmospheric pressure. As a result, this moisture naturally condenses and accumulates within the compressor system.

The Inevitable Moisture Buildup

As the compressor operates, it continually pulls in new air and with it, more moisture. This is not a sign of a malfunctioning compressor but a natural consequence of air compression. The critical factor here is not the presence of moisture but the management of it.

Why Draining is Crucial

Neglecting to drain this accumulated moisture can lead to a host of problems. The most immediate is the reduced efficiency of the compressor. When water mixes with the oil in the system, it affects lubrication, leading to increased wear and tear. But the impact goes beyond just the compressor itself.

Corrosion: The Silent Culprit

Over time, moisture will start to corrode the internal components of the compressor, such as the valves and tanks. This corrosion shortens the lifespan of the compressor and can also lead to costly repairs.

The Far-Reaching Impact of Moisture

The effects of moisture don’t stop at the compressor. When it makes its way into the compressed air supply, it can damage the tools and machinery that rely on this air. This is particularly problematic in applications where dry air is critical, such as in woodworking or sandblasting. The presence of water can lead to poor finishes, clogged tools, and even failure of pneumatic controls.

Draining your air compressor isn’t just about maintaining the compressor; it’s about protecting the entire system and the applications it supports. It’s a simple yet vital routine that preserves the efficiency, reliability, and longevity of your compressed air system.

How to Drain Moisture from an Air Compressor

Having understood the critical importance of draining your air compressor to prevent moisture build-up and its detrimental effects, let’s jump into the practical steps of this task. Remember, regular draining is key to maintaining the health and efficiency of your air compressor and the entire compressed air system.

Understanding Your Air System Components

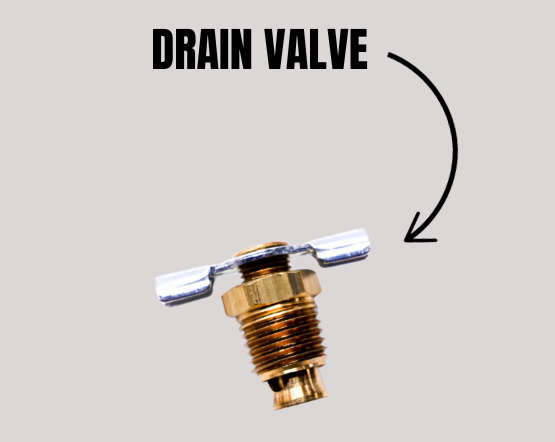

Before we start, it’s crucial to have a basic understanding of your air system components. The main parts involved in the draining process include the drain valve, aftercooler, receiver tank, and distribution system. Each plays a vital role in the operation and maintenance of your air compressor.

Step-by-Step Guide to Draining an Air Compressor

- Turn Off the Compressor: Ensure that your air compressor is turned off. This prevents any additional pressure build-up while you are performing the maintenance.

- Release Pressure: Safely release any residual pressure from the air tank. This can be done by opening the pressure release valve.

- Locating and Releasing the Drain Valve: The drain valve is typically located at the bottom of the air compressor tank. In some systems, you might also find a drain valve on the after-cooler. Depending on your compressor model, you might have a manual drain valve, which requires you to open it manually, or an automatic drain valve that does the job automatically at set intervals. Open the drain valve by pulling the ring and allow all the water and moisture to flow out. If your system has an automatic drain valve, check it periodically to ensure it’s functioning correctly.

- Close the Drain Valve: Once all the moisture is drained, securely close the drain valve.

- Draining Frequency: For manual drain valves, it’s recommended to drain your air compressor after each use or at least daily, depending on the humidity levels and usage frequency.

Draining Other Air System Components

Besides the air compressor itself, other components in your compressed air system need regular draining, such as air dryers, receiver tanks, and the piping system. These components can also accumulate moisture and should be included in your regular maintenance routine.

How to Drain These Other Components

- Air Dryers and Receiver Tanks: Similar to the air compressor, locate the drain valves and release any accumulated moisture.

- Piping System: Check for any low points where moisture might collect and ensure they are drained properly. Many piping systems will have a drain valve underneath the drip leg which is placed at the optimal low point.

By following these steps, you can effectively manage moisture in your air compressor and the entire compressed air system, ensuring optimal performance and longevity. Regular maintenance, like draining, is a small investment of time and effort that pays off significantly in the long run.

Is There Anyone I Can Hire to Drain My Air Compressor and System Regularly?

Now that you understand the importance of draining your air compressor and its process, you might be wondering if there are other ways to ensure the longevity of your system. The good news is, there is professional help available.

The Importance of Professional Maintenance

Proper maintenance of your air compressor is not just about draining the moisture; it’s about ensuring the entire system functions efficiently and has a long lifespan. While the steps provided in this guide are straightforward, they do require time, consistency, and a certain level of technical know-how. This is where Advanced Air & Vacuum steps in.

Advanced Air & Vacuum: Your Maintenance Partner

At Advanced Air & Vacuum, we understand the critical role air compressors play in your business or home projects. That’s why we offer comprehensive maintenance services, including regular draining of air compressors and compressed air systems. Our team of experts is equipped with the knowledge, skills, and tools to handle this essential task and much more, ensuring your system remains in prime condition.

Contact Us for Reliable Air Compressor Maintenance

If you’re interested in learning more about our services or scheduling a maintenance appointment, please don’t hesitate to contact us. At Advanced Air & Vacuum, we are always ready to assist you in keeping your compressed air system operating smoothly and efficiently.