Air compressors are the unsung heroes of many industries. Whether it’s powering tools in a workshop or playing a crucial role in large-scale manufacturing processes, these machines are everywhere, yet often unnoticed. But at the core of each air compressor lies its heart: the oil. This vital component ensures smooth operation, keeps things cool, and extends the life of the machine. But what exactly is air compressor oil? And why is it so critical? In simple terms, air compressor oil serves as the lifeblood for the machine. Much like how motor oil is essential for an automobile engine, compressor oil ensures the air compressor runs efficiently and lasts longer. It provides necessary lubrication to the moving parts, keeps the compressor cool during operation, and can even help in sealing and preventing corrosion. To truly grasp the significance of air compressor oil, we must dive deeper into its mechanics, types, and best practices.

The Science Behind Air Compressor Oil: Why It’s Essential

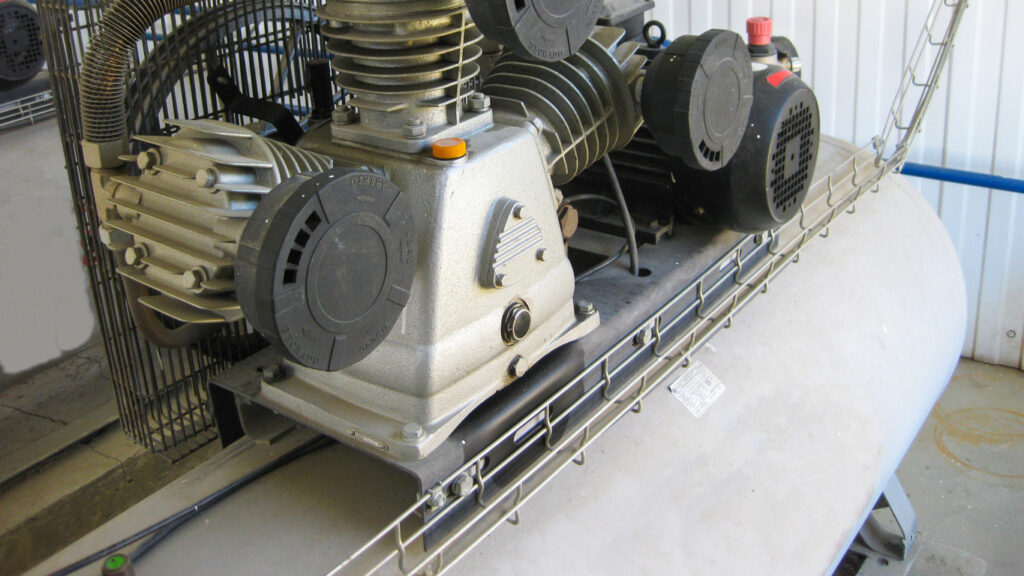

The efficiency of air compressors rest on the seamless interplay of numerous components, with compressor oil being the linchpin. But what makes this oil so indispensable? At its essence, an air compressor works by compressing air—a task that seems simple yet involves countless moving parts vulnerable to wear. Compressor oils, be they synthetic, motor, or mineral-based, serve as lubricants for these parts. This lubrication ensures the machine operates without hitches, minimizing friction and potential malfunctions. Another crucial role of the compressor oil is as a cooling agent. As they function, especially in industrial contexts, compressors generate substantial heat. The unique properties of the oil assist in dissipating this intense heat, ensuring the equipment doesn’t overheat and consistently runs at peak efficiency. It’s worth noting, however, that not all compressors utilize oil. There are oil-free compressors designed for scenarios where impeccably clean compressed air is vital. But in many industrial environments, oil-lubricated compressors reign supreme. Equipped with tools like oil and water separators, these machines are renowned for their resilience and suitability for rigorous tasks. Clean compressed air is a non-negotiable, particularly in certain industrial operations. This is where the oil, paired with devices like oil separators and air filters, becomes invaluable. It captures and eliminates contaminants, guaranteeing that the discharged compressed air is of unparalleled purity. Furthermore, the oil acts as a protector. Air compressor systems, laden with metal parts, are prone to corrosion over time. By enveloping these components, the oil defends them against moisture and possible corrosion, thereby extending the compressor’s longevity.

Types of Air Compressor Oil

Given the diverse array of compressors and their unique requirements, it’s vital to make informed choices to ensure optimal performance. Below, we’ll dive into the different types of air compressor oils, their distinct characteristics, and best-fit applications.

- Synthetic Oil: Derived from a synthetic base, synthetic oil is the pinnacle of advanced engineering. It’s tailored for extreme conditions and offers superior protection against wear, rust, and oxidation. With its high resistance to extreme heat and ability to maintain viscosity in varying temperatures, it’s a popular choice for rotary screw air compressors and those used in high-demand environments.

- Mineral Oil: Extracted from natural sources, mineral oil has been the traditional choice for several decades. It’s best suited for general-purpose applications and offers a balance between performance and cost. While it might not boast the extended lifespan of synthetic oils, it’s reliable for routine applications, especially in stationary compressors.

- Hydraulic Oil: Although primarily designed for hydraulic systems, hydraulic oil can sometimes be used in air compressors, especially those designed for industrial applications. Its superior anti-wear properties and ability to handle high pressures make it a feasible choice in specific compressor settings.

- Standard Oil: This is the general-purpose oil that’s often recommended by manufacturers for a broad range of air compressor systems. Following the manufacturer’s recommendations is crucial here. Using standard oil in systems that require specialized oil can hinder performance and reduce the life span of the compressor element.

- Special Mention – Oil-Free Compressors: As touched upon earlier, there are compressors designed to function without oil. These oil-free air compressors, often found in medical or food industries, rely on materials like Teflon for lubrication. While they ensure absolutely pure compressed air, their maintenance and life span might differ from their oil-lubricated counterparts.

By understanding the nuances of different oils and their applications, you’re not just ensuring your compressor’s efficient operation but also safeguarding a significant investment.

How to Choose the Right Air Compressor Oil

Selecting the right oil for an air compressor isn’t as straightforward as one might presume. Given the diverse array of compressors and their unique requirements, it’s vital to make informed choices to ensure optimal performance. While it’s tempting to opt for the most advanced or the most economical option available, it’s paramount to consider the specific requirements of your air compressor. For instance, rotary screw air compressors may benefit more from synthetic oil due to their continuous operation, while a portable compressor might do just fine with mineral oil. Another factor to consider is the environment. Extreme conditions, such as very high or low temperatures, may necessitate specialized oils.

Best Practices for Maintaining Your Air Compressor’s Oil System

An air compressor is a significant investment, both in terms of finance and its pivotal role in operations. Therefore, ensuring it runs efficiently and lasts long is essential. A lot of that comes down to the oil system’s proper maintenance. Let’s uncover some best practices and maintenance guidelines for your compressor’s oil system.

- Checking the Oil Level: Much like checking your car’s engine oil, regularly inspecting the oil level in your air compressor is crucial. A dipstick or sight glass is typically available for this purpose. Ensuring that the oil level is maintained within the recommended range guarantees optimal lubrication without risking any overflows.

- Oil Change Intervals: Depending on the type of oil you use—be it synthetic oil, mineral oil, or hydraulic oil—change intervals will vary. For instance, synthetic oil might offer a longer interval compared to mineral oil. Always refer to the manufacturer’s recommendations for accurate intervals, and be consistent with oil changes to ensure longevity and optimal performance.

- Monitoring Oil Quality: Oil doesn’t just lubricate but also traps contaminants. Over time, this can degrade its quality. Regularly inspect the oil for any signs of contamination, including darkening or the presence of particles. Any deterioration in quality might necessitate an earlier oil change.

- Oil Filters and Separators: Oil filters and separators play an integral role in ensuring the purity of both the oil and the compressed air. These components need routine maintenance. Regularly checking and replacing filters can prevent excessive wear and tear and uphold the quality of compressed air.

- Avoiding Oil Carryover: Excessive oil in the compressed air, known as oil carryover, can be detrimental. It can degrade the quality of the compressed air and lead to potential downstream issues. Regular maintenance, adhering to oil level recommendations, and ensuring the use of quality oil separators can mitigate this issue.

- Understanding Oil-Free Systems: For oil-free air compressors, while you don’t have to worry about oil changes, you should be vigilant about the wear of the components. Periodic checks for signs of wear or any inefficiencies are essential.

- General Guidelines for Maintenance: Beyond just the oil system, ensure your air compressor undergoes routine maintenance. Check for any leaks, inspect air filters, and monitor energy consumption. Regular servicing can detect potential issues early on, reducing maintenance costs in the long run.

- Consultation with Experts: There’s no one-size-fits-all approach to maintenance. Depending on your operational demands, environment, and the specific model of your air compressor, maintenance requirements can vary. This is where the insights from experts, like the team at Advanced Air & Vacuum, can be invaluable.

To sum it up, while selecting the right oil is vital, it’s just the beginning. Ensuring a consistent maintenance regime amplifies the benefits of that choice, granting your air compressor a long and efficient life. In our final section, we’ll delve into the broader picture, exploring the overarching benefits of investing in quality and maintenance in the realm of compressed air systems.

Operator recording routine operation oil check.

Benefits of Investing in Maintenance for Air Compressors

Investing wisely in air compressors entails more than just an initial purchase; it encompasses a commitment to quality and consistent maintenance. High-grade compressor oil paired with regular maintenance can substantially extend your equipment’s lifespan, ensuring smooth, energy-efficient operations. These proactive measures not only avert expensive breakdowns, minimizing maintenance costs but also guarantee the production of high caliber compressed air vital for many industries. Furthermore, it bolsters safety, ensuring compliance with industry standards. Downtimes can be detrimental to a business’s revenue and reputation. By emphasizing quality and regular upkeep, businesses can establish themselves as reliable industry players. Collaborating with experts like Advanced Air & Vacuum provides an added advantage, granting access to unparalleled advice and support. In essence, delving into the world of air compressors with an emphasis on quality is an investment in future success. Click here to contact the AAV team today.