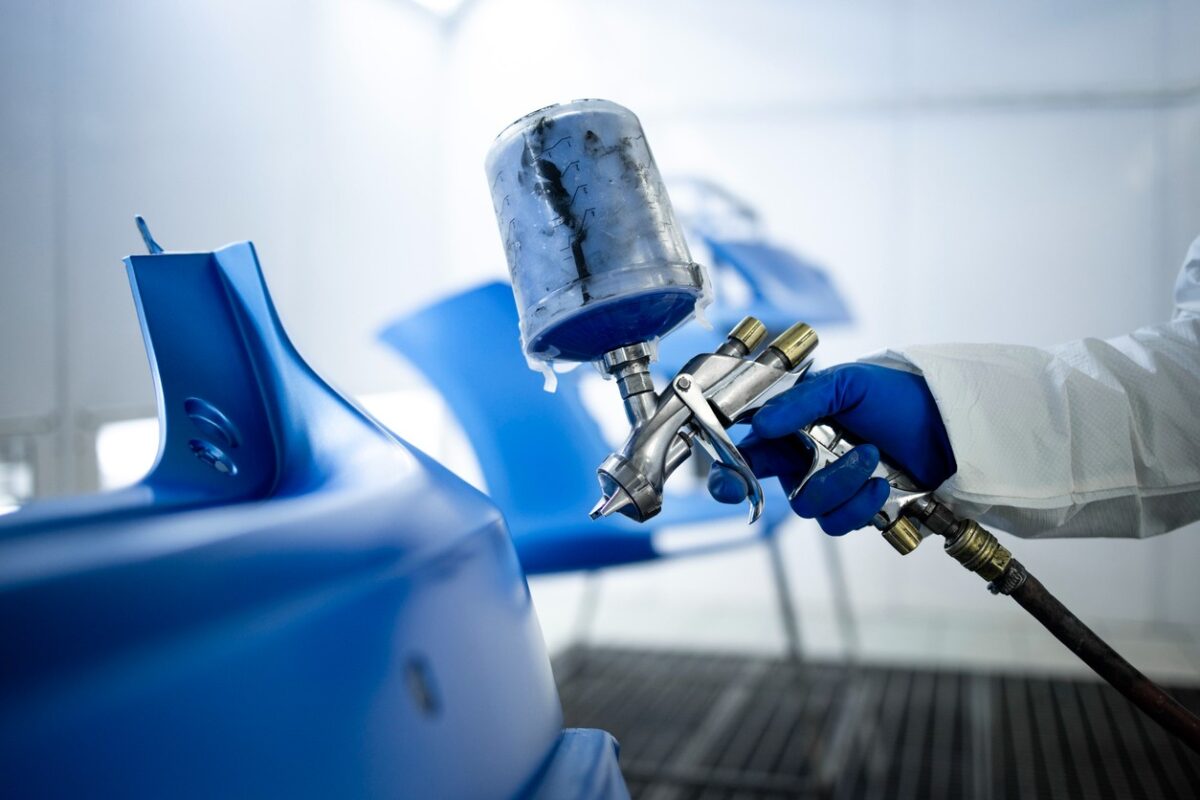

When your business is spray painting car bodies, you need an air compressor that provides steady compressed air at continuous air pressure. You’ve invested a lot into your auto body operation and having the best air compressor is often as important as having the perfect HVLP gun to get the right finish. This means that not just any air compressor will do. How do you find the perfect size air compressor for your operation? In this article, we’ll look at factors you should consider, air compressor features that will impact your operation, and some of the best air compressors for your needs.

Factors to Consider

To start, let’s look at what your needs are to ensure that you’re getting the right air compressor for your requirements.

CFM

Many individuals who work with multiple pneumatic tool types may not realize the importance of CFM, or cubic feet per minute, in determining the appropriate type of air compressor for their needs. However, automotive painting requires not only constant pressurized air, but also specific quantities of it. A small compressor may be able to provide sufficient compressed air for operating a wide range of air tool types, but because a paint sprayer provides continuous flow to deliver the best results, it requires a much higher volume of air on a regular basis. If the spray gun were only used for a few seconds at a time, a small compressor might be able to do the job. Still, paint spray processes often require the paint gun to be used continuously for longer periods of time during the painting job to ensure that the car paint comes out with a similar texture across the entire vehicle.

Air Pressure

When using spray guns for large projects such as auto painting, the air pressure must be high enough to provide consistent results. Low pressure can put the paint droplets on in too large of a size, preventing the paint from laying down smoothly or causing runners to form. Your sprayer will come with specific requirements that should be followed carefully, both in terms of volume per minute, or airflow, as well as air pressure, or PSI. Having the right air pressure ensures that you can complete your auto painting project smoothly and effectively, providing a high-quality finish to the vehicle you’re working on. However, if you’re going to be using another pneumatic tool or tools at the same time off of the same air compressor, it’s important to keep their total air pressure and airflow needs in mind when selecting your air compressor to prevent pressure drops when a new air hose is attached to the compressor, or another high-flow pneumatic tool causes a low pressure situation to form in your shop.

Tank Size

If you’re wondering how large of a tank you’ll need for your automotive painting operation, both the best and most annoying answer is “it depends.” How many paint guns will you be running at the same time? Will you be running other pneumatic tools at the same time? From that information, you can calculate your absolute maximum air demand and then add a buffer, just in case you get a new air tool or paint gun that has higher demand than the previous one. From there, you can calculate how big of a storage tank size you’ll want to have available for additional air storage. You should also take into account the duty cycle of your air compressor so that the air stored in the tank provides sufficient flow and pressure to keep your shop moving while your air compressor is resting.

Horsepower

The horsepower of your air compressor is often tied in with other common factors, including the stages, type of compressor (more on that in a few moments), tank size, overall pressure, overall airflow, voltage, and similar issues. Overall, you’ll want to have an air compressor that is capable of around 3 horsepower for single-tool operations, such as one-man shops where only a single tool is used at a time. For multi-person shops, 5 horsepower is a minimum, and large shops will want a production air compressor of 10 horsepower or much larger, depending on how much production you push through on a daily basis. Horsepower is tied to the common factors mentioned above, as larger horse motors will require higher voltage while providing higher pressure, airflow, and larger tanks.

Which Type of Air Compressor Should I Use?

Single vs. Two Stage

If you’re a hobbyist or a very small shop, you may be able to get by with a single-stage air compressor system, provided that it’s large enough to keep up with your paint sprayer gun. You’ll still want to go with a compressor that has a larger storage tank and higher horsepower to be able to keep up with airflow and PSI demands. However, if you’re doing end-to-end bodywork with just yourself or one other individual in the shop or can split the work so that there is minimal draw-down of the air compressor during your painting operations, you’ll be able to keep up with your work with a single-stage compressor with a bit of creativity. These air compressors also nearly always use 115V power, reducing the need for you to have to rewire your shop to be able to use the air compressor. This can be a big boon to someone who is starting out their business in their garage but may need to be remedied down the road to expand your business operations to a professional shop.

Generally speaking, to get more out of your storage tank, you’ll want to look at a two-stage compressor over a single-stage compressor. This is because a two-stage or dual-stage compressor will take two steps to provide further compression of the air, reaching pressures as high as 175 PSI. They also tend to have longer duty cycles, as well as a range of features built in to help you work longer and easier, which is one of the main reasons for having a solid air compressor system in your shop to begin with. Dual-stage compressors meet a wide range of needs, allowing you to run your entire shop from a single compressor. However, you may need to install a special electrical service, as many two-stage air compressors require 230V power, and those that do not will still often require a switch to 20-amp service in 115V power, requiring a new plug, and sometimes new wiring, to be run to the breaker box for operation.

Rotary Screw Compressor vs Reciprocating Air Compressors

If you’re wondering about the differences between reciprocating air compressors versus rotary screw compressor systems, you’re not alone. As you reach higher levels of demand on your air compressor system, you may want to make the change. The single and two-stage compressors mentioned above both use pistons that reciprocate, or move back and forth in their shafts, to compress air. This provides a relatively simple way of compressing the air before it is moved into the storage tank for future use. However, rotary screw compressors can be a boon for high-demand systems, especially when maintaining consistent air pressure and flow is of vital importance for your spray guns.

A rotary screw compressor rotates to compress air and move it into your compressed air lines, essentially creating pressure and flow during the motion and providing superior performance for your operation. This type of air compressor typically drives large quantities of air in a continuous, highly pressurized manner. Because it has a very short rest, if any, rest period during its duty cycle, rotary screw air compressors are considered the gold standard in the industry, providing the most reliable air for pneumatic tools. If you have the ability to switch up to this type of air compressor, it is highly recommended in the industry.

The Advanced Air Difference

When you’re working with Advanced Air & Vacuum, you’ll get the best possible service, information, and assistance in the industry. Our many years of experience in the area means that we can provide you with solid solutions to your needs, from compressed air piping to industry-leading advice. We stand behind our products and ensure that you’ll get the right products for your needs. For automotive painting, we recommend the following products:

- Our 20-Gallon Single-Stage Air Compressor is good for small operations, though you’ll need to check your spray gun for requirements.

- Our 5-7.5 Vertical Two-Stage Air Compressor has an 80-gallon tank to keep your operation in motion without taking up a lot of floor space.

- We have a wide range of rotary screw air compressors available.

Ready to get started with the perfect air compressor for your auto body shop’s needs? We’re ready to help. Please feel free to reach out to Advanced Air for more details, with any questions, or to get started on a smart design that will keep your operation in motion.