Table of Contents

What is an Air Compressor Governor and What Does It Do?

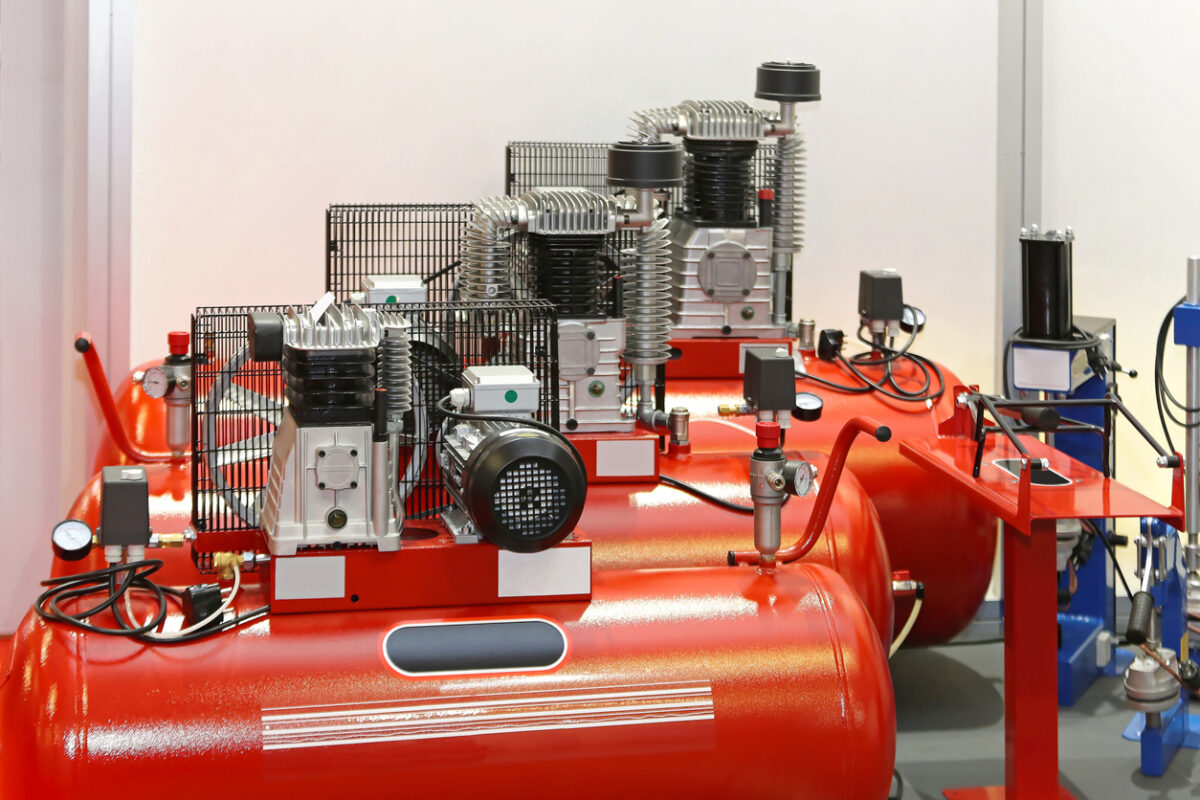

An air compressor is made up of several components, one of which is the governor.

The governor regulates the amount of air pressure generated within an air compressor, usually measured in pounds per square inch (psi). It operates based on preset minimum and maximum air pressure levels to prevent overly high pressure that could break the system. When the pressure reaches a specific cut-out pressure, which is the maximum pressure limit set to prevent excessive pressure build-up, the governor signals the compressor to stop pumping air.

Conversely, once the air pressure decreases to below the cut-in pressure threshold, which is the minimum pressure required to ensure the system operates effectively, the governor signals the compressor to start the loading phase and build air pressure again. So, how does it work?

How a Governor Works

Similar to how the thermostat in your home keeps the temperature within a comfortable range, the governor retains the air pressure within an appropriate range to ensure the system has the appropriate pressure to function correctly.

Firstly, the governor is connected to the system by an airline. Once the air pressure starts to build in the air system, reaching its maximum, or cut-out pressure, the governor, detecting this higher pressure, prompts the unloader mechanism to open. This specifically designed unloader port now allows the air to bypass, diverting it away from the air compressor and hence ceasing any further inflation.

As the system operates, the air pressure diminishes. The moment this system pressure descends below the minimum, or cut-in pressure, the unloader mechanism in the governor ceases discharging the air. Instantly, the compressor restarts building air, continuing until reaching the cut-out pressure again. During this process, the governor also interacts with the purge valve. When the governor signals the unloader mechanism, it simultaneously activates the purge valve in the air dryer system. This valve opens to release moisture and contaminants collected during the compression phase, ensuring that only dry, clean air is circulated back into the system. This is a continuous cycle that ensures the air system is responsive and maintains optimum pressure for operations.

Controlling the Speed

The governor plays a pivotal role in controlling the speed of an air compressor by adjusting how quickly the compressor cycles between the cut-in and cut-out pressures. By fine-tuning these settings, operators can manage the frequency and duration of the compressor’s run times, which directly impacts energy consumption and wear on the compressor. Adjusting these parameters allows for better control over the compressor’s speed, leading to more precise management of airflow and pressure, which can be particularly beneficial in applications requiring a consistent delivery of compressed air over a long period.

Can a Governor be Adjusted?

Adjusting a governor involves setting the cut-in and cut-out pressure thresholds to the desired levels. This is typically done by turning a screw on the governor, which changes the tension on a spring inside the device. The tension adjustment affects when the governor activates the unloader mechanism, thus controlling when the compressor stops and starts pumping air.

It’s important to consult the compressor’s manual or a professional technician when making these adjustments to ensure they are done correctly and safely. Incorrect adjustments can lead to system inefficiencies, increased wear and tear, or safety hazards.

Troubleshooting and Maintaining Your Governor

The value of an air compressor relies on its smooth and efficient operation. In case you’re experiencing trouble with your air compressor not building pressure, there might be issues with your governor. Here are some common issues and how to deal with them:

1. Leaks: If your system cannot hold a consistent tank pressure, it is often a result of a leak or multiple leaks. To detect leaks, listen for a hissing or whistling noise and apply a mixture of soapy water around the area, and look for bubbles indicating the presence of an air leak. If bubbles are present, there is a leak that needs to be sealed or replaced.

2. Fluctuation in Air Pressure: A faulty governor could lead to a constant fluctuation in air pressure so keep an eye on your air pressure gauge. If the cut-out or the cut-in psi is inconsistent or fluctuates wildly, your governor could be faulty and may need to be replaced.

3. Sticking Unloader Valve: Sometimes the unloader valve may stick in the ‘loaded’ or ‘unloaded’ position, disrupting the normal cycling of air pressure. Lubricating the valve and checking for dirt or debris can often resolve this issue but if the problem persists, the valve may need to be replaced.

4. Worn Internal Components: Over time, internal components of the governor such as springs or pistons can wear out, so perform periodic inspections and replace worn parts to prevent failure.

5. Inaccurate Pressure Settings: Incorrect calibration of the governor can lead to improper pressure settings, causing the air compressor to either overwork or underperform. Recalibrate the governor periodically, especially after repairs or replacement of parts, to ensure that the governor operates within the designated pressure settings.

6. Improper Installation: If the governor or its connections are not installed correctly, it can lead to various issues including leaks, pressure imbalances, and other operational failures. So, ensure that all connections are secure and that the governor is mounted according to manufacturer specifications to prevent such issues.

Air Compressor and Vacuum Pump Solutions at Advanced Air & Vacuum

An efficiently performing governor plays a crucial role in ensuring an air compressor is operating within its optimal pressure range. Governors that do not consistently perform can lead to a range of issues and malfunctions in your air system. That’s why having a trusted expert in the field is key.

At Advanced Air & Vacuum, we’re here to provide solutions for all your air compressor and vacuum pump needs. Our unique approach not only includes installing, repairing, maintaining, and selling nearly every recognized air compressor and vacuum pump manufacturer but also providing consultation on upcoming projects. Using years of experience, our technicians work closely with you and your team to ensure the most suitable equipment is used in every job.

Whether you need a new air compressor, help to install a compressor, or someone to repair or perform maintenance on your current air system, AAV is your one-stop shop for professional-grade air compressor services. For expert advice or to explore how AAV can help you, contact us or give us a call.