What is A Vacuum Pump?

When you think of a vacuum pump, it’s common to think of the vacuum cleaner in your closet at home. However, a vacuum pump is a mechanical device used in various air compressor systems, specifically designed to remove air or gas from a sealed area to create a low-pressure or negative-pressure environment, often referred to as a vacuum. These pumps, though seemingly unimportant, have a wide variety of uses and applications across numerous industries.

Measuring the Performance of Vacuum Pumps

The performance of vacuum pumps is typically measured by several key parameters:

- Ultimate Pressure – This is the lowest pressure that the vacuum pump can achieve, usually measured in torr or millibar, and is a critical measure for applications requiring very low pressures.

- Pumping Speed – Expressed in volume per unit time (such as cubic feet per minute, CFM), this indicates how quickly a vacuum pump can evacuate air from a space. Higher pumping speeds translate to faster evacuation times, which is vital for high-throughput industrial processes.

- Throughput – This refers to the amount of gas that can be processed by the pump in a given time, often correlated with the pump’s ability to handle gas loads effectively.

- Power Consumption – Understanding how much energy a vacuum pump consumes during operation is essential for assessing its efficiency and operating cost.

- Leakage Rate – The rate at which air or gas leaks back into the vacuumed space. A lower leakage rate indicates a more efficient vacuum seal, which is particularly important in maintaining high vacuum levels over time.

- Compression Ratio: This measurement indicates the pump’s capability to compress the gas from its entry point to its discharge point and helps determine the efficiency of a vacuum pump in reaching and maintaining desired vacuum levels.

The Science Behind Different Vacuum Pumps

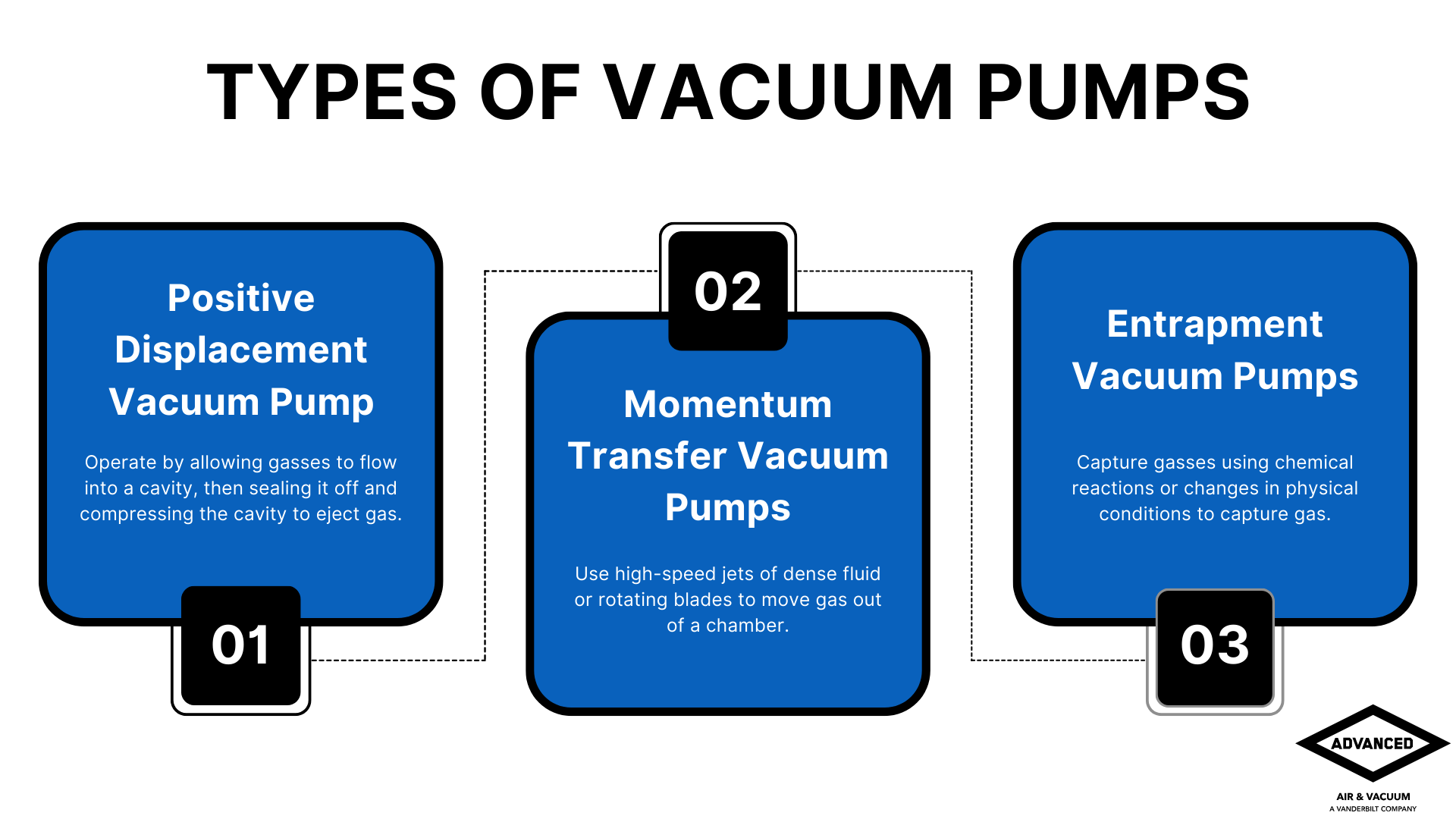

A vacuum pump operates by removing gas or air molecules from a confined space, creating a vacuum within that space. They do this via a mechanical, pneumatic, or hydraulic process, depending on the type of vacuum pump. There are primarily three main types of vacuum pumps: positive displacement pumps, momentum transfer pumps, and entrapment pumps.

Positive Displacement Vacuum Pumps

Positive displacement vacuum pumps are the most common type of vacuum pump and operate by mechanically expanding a cavity, allowing gasses to flow, then sealing off and compressing the cavity to eject the gasses into the atmosphere or another chamber. This type is particularly effective for creating low vacuums and is widely used due to its simplicity. The most common types of positive displacement pumps include:

- Piston Pumps – Utilize a piston moving back and forth in a cylinder to compress and move the gas.

- Diaphragm Pumps – Use a flexible diaphragm that moves up and down to create vacuum conditions without contaminating the gas with lubricants.

- Liquid Ring Vacuum Pumps – Employ a rotating impeller and sealing liquid (typically water) to create a vacuum by forming a liquid ring within the pump.

- Rotary Vane Vacuum Pumps – Contain a rotor with sliding vanes that press against the housing of the pump, trapping gas and moving it through the pump system.

- Scroll Pumps – Involve two spiral-shaped scrolls, where one remains stationary and the other orbits to trap and move gas toward the exhaust.

Momentum Transfer Vacuum Pumps

Also known as molecular pumps, these use high-speed jets of dense fluid or rotating blades to propel gas molecules out of the chamber. This type of pump is particularly useful when a higher vacuum level is required.

Entrapment Vacuum Pumps

These pumps capture gasses using chemical reactions or changes in physical conditions to capture and contain gas molecules. They are used for creating ultra-high vacuums and generally do not have moving parts, which minimizes maintenance.

Each type of vacuum pump offers distinct advantages and is suited to particular applications. It is essential to select the right type to ensure efficiency and effectiveness in any given application.

Uses and Applications of Vacuum Pumps

Vacuum pumps are critical machines used for various applications across a handful of industries.

Industrial Applications of Vacuum Pumps

Composite Molding

Vacuum pumps are used to evacuate air from molding applications, ensuring materials bond without any air pockets, which could compromise structural integrity.

Manufacturing

Vacuum pumps drive manufacturing processes across various industries, to ensure precision and quality, whether in casting automotive parts, etching semiconductor layers, or building products in airtight environments. Their ability to remove air and control environments helps in achieving the high standards required in modern manufacturing.

Packaging Industry

Vacuum pumps are used to ensure that food, pharmaceuticals, and electronics are packaged in clean, air-free environments to extend the shelf life of perishable goods and protect sensitive components from atmospheric conditions that could lead to corrosion or failure. Vacuum packaging is also used to reduce the package volume, which helps in reducing shipping and storage costs.

Scientific and Research Applications

Laboratory Research

Vacuum pumps are commonly found in laboratories where they are used with instruments and applications that require low-pressure environments to function correctly.

Space Exploration

Vacuum pumps are capable of creating the near-perfect conditions found in outer space, facilitating the simulation of space environments for testing spacecraft and other equipment.

Environmental Research

Vacuum pumps are used in climate research and pollution control technologies to help in sampling and analyzing air and other environmental samples, helping monitor and combat pollution.

Flight Instruments

Vacuum pumps are essential for operating various flight instruments that rely on air pressure differences to function accurately. These instruments include altimeters, gyroscopes, and airspeed indicators, which are crucial for navigation and safety in flight.

Medical and Healthcare Applications

Surgical Applications

Vacuum pumps are used in various surgical procedures where they help in maintaining sterile environments or in powering pneumatic devices.

Pharmaceutical Manufacturing

The production of sterile pharmaceutical products relies heavily on vacuum technology to prevent contamination during the manufacturing process.

Dentistry

Vacuum pumps are used in dental practices and labs to maintain cleanliness, power pneumatic tools, create precise molds for crowns and bridges, minimize imperfections, and several other applications.

Everyday and Miscellaneous Uses

Automotive Industry

Vacuum pumps are used in automotive body shops and car washes for various applications, including the operation of pneumatic tools, tire inflation systems, and car lifts.

Food and Beverage Industry

Vacuum pumps help in the preservation and packaging of food and beverages, extending shelf life and maintaining quality by removing air from packaging.

Construction and Building

Vacuum pumps are used for a variety of machines, like HVAC systems and other construction-related applications, including material handling, concrete molding, sandblasting, and the installation of vacuum-insulated glass.

Maintenance and Care Tips

A vacuum pump, like any other machine, requires regular maintenance and care to ensure it keeps delivering high performance and lasts for a long time. Irrespective of the industry or usage, certain aspects of vacuum pump maintenance prove crucial. Here are some tips to help you maintain your vacuum pump:

- Regular Inspections: Conduct periodic checks to identify early signs of wear and tear or contamination, which could lead to decreased efficiency.

- Oil Changes: For oil-lubricated pumps, changing the oil regularly is essential for smooth operation and to extend the pump’s lifespan.

- Maintenance Schedules: Adhere to maintenance schedules that suit your pump type, usage intensity, and application to avoid unexpected breakdowns.

- Consider Environmental Factors: Pumps in dusty or corrosive environments need more frequent servicing so ensure the environment is suitable for your pump’s material and design.

- Temperature Control: Operate the pump within the recommended temperature range to prevent material damage and maintain efficiency.

- Proactive Servicing: Avoid costly repairs and replacements through proactive maintenance and timely servicing.

Maintaining a vacuum pump may seem like a tedious task, but neglecting this critical aspect can lead to larger issues down the line. With regular inspection, cleaning, and timely service, you can ensure that your vacuum pump serves you efficiently.

How Advanced Air and Vacuum Can Help

If you’re looking to use and incorporate an industrial vacuum pump into your operations, look no further than AAV. With a broad selection of air compressors and vacuum pumps from industry leaders like Quincy and Atlas Copco, our service technicians are equipped to guide you in selecting the equipment tailored to your specific needs. From installation, emergency repair, and maintenance to tailored advice on optimizing your systems, we ensure that your operations are not hindered by a faulty vacuum pump. For expert assistance and more information on how our services can benefit your specific applications, fill out a form or give us a call.