Jump To:

Replacing An Air Compressor Tank

The air compressor tank is the reservoir of pressurized air, and it’s crucial for the function of your air compressor. A sturdy and high-functioning compressor tank safeguards the quality of the air you use and increases efficiency in operation. Even the best-maintained air compressors will need to have their tanks replaced at some point, owing to wear and tear and the constant pressure the tanks are subjected to.

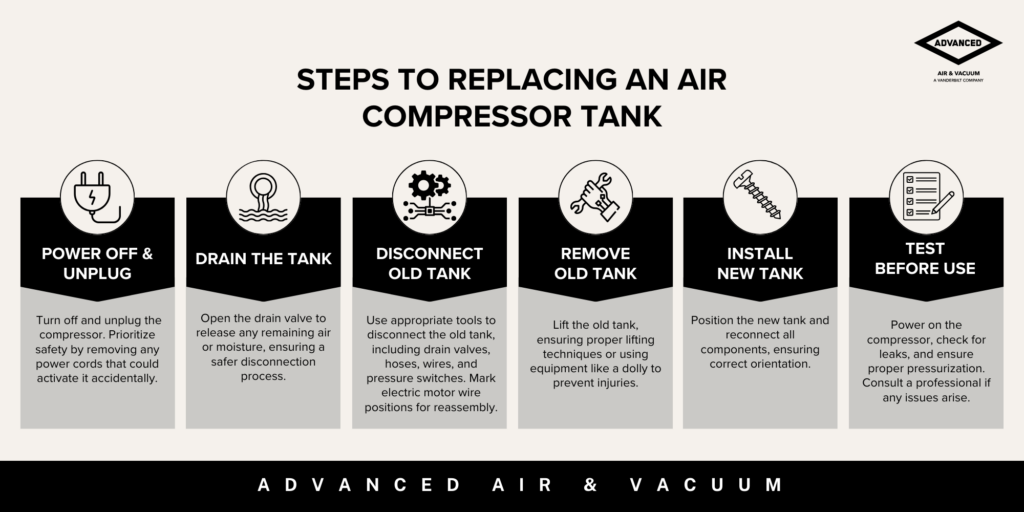

Steps To Replacing An Air Compressor Tank

To successfully replace your air compressor tank, you will need a variety of tools including a drill with different-sized sockets for removing and attaching bolts, a flathead screwdriver, a Phillips head screwdriver, and a pair of pliers or an adjustable crescent wrench. In addition to using these tools, knowing the components of an air compressor and their placement will make this process much easier and smoother.

1. Power Off:

The first and most important step is to turn off and unplug the air compressor. Remove any power cords that could turn on the air compressor and remember that safety should be your primary concern. Always double-check that the compressor is completely powered down before proceeding with any maintenance tasks.

2. Drain the tank:

Next, release the drain valve located at the tank bottom to get rid of any residual moisture or air. Allowing the tank to fully drain will ensure a safer and simpler disconnection process.

3. Disconnect the old tank:

Once emptied, use the right tools to disconnect the old tank and detach any drain valves, hoses, pipelines, wires, and pressure switches. Be very mindful of the electric motor wires and mark or photograph their positions to aid with reassembly. Take care to inspect the condition of all components for any signs of wear or damage that may need attention during the replacement process.

4. Remove the old tank:

This stage might need some muscle. Compressor tanks, particularly the larger gallon tanks, can be heavy. Be sure to lift properly or use equipment aid like a dolly to avoid injury. Take your time during this step to ensure the old tank is removed safely and without causing damage to surrounding equipment or structures.

5. Install the new tank:

Position the new air tank and carefully reconnect all drain valves, hoses, pipelines, wires, and pressure switches, ensuring that the new tank is oriented correctly. Double-check all connections to ensure they are secure and properly tightened to prevent any leaks or malfunctions once the compressor is back in operation.

6. Test before final use:

Before you begin using your new compressor tank, ensure that everything’s been installed correctly. Turn the power on, allow it to pressurize, and watch for leaks or other issues. If you run into any problems, turn the system off immediately and consult a professional.

When you face compressor tank failure, check the relief valve, automatic drain valve, and pressure switch to see if these components need replacement parts before deciding to install an entirely new compressor tank. However, if you aren’t comfortable tackling this task yourself, we recommend seeking the expertise of a professional to ensure the best results and to guarantee that that installation is performed safely and correctly.

Common Reasons For Replacing An Air Compressor Tank

So, how do you know when it’s time to replace your compressor tank?

Generally, a well-maintained air compressor tank has a lifespan of 10 to 12 years. However, this timeline varies based on the type of compressor, frequency of use, and the conditions it operates in, including temperature and humidity levels. As with any mechanical or technical process, replacing an air compressor tank comes with its unique challenges.

1. Air and Pinhole Leaks

Air and pinhole leaks are quite common in older compressor tanks that have not been properly maintained. It’s important to look for small pinhole leaks because if left unattended, they can lead to bigger issues like a tank rupture. If you discover any pinholes in your tank, you should replace the tank immediately. Using sealing products may provide a temporary fix, but over time, this could pose a safety risk.

2. Corrosion

Corrosion is a natural enemy of compressor tanks, often resulting from exposure to moisture over time. When corrosion becomes significant, it weakens the tank’s structure, requiring replacement to avoid failure.

3. Damage

Physical damage from accidents or misuse can compromise the safety and functionality of an air compressor tank. Even minor dents or deformities can affect performance, making replacement the safer and more efficient choice.

4. Capacity Needs

Upgrading to a larger compressor tank might be necessary as your air demand grows. A tank that’s too small for your needs can lead to frequent cycling of the compressor, reducing efficiency and increasing wear.

5. Age

Over time, even well-maintained tanks will succumb to wear and tear. An aging tank may not yet show visible signs of failure but replacing it proactively can avoid unexpected downtime and potential hazards.

6. Performance

It’s important to be observant of changes in the air compressor’s performance. An increase in the time it takes your compressor to pressurize, a noticeable decrease in power and air pressure, continuous cycling, or distributed air that is too moist or oily are clear signs and causes for concern and replacement.

Remember, the cost of neglecting signs of a failing air compressor tank can be enormous, causing higher energy consumption, compressor failure, or even a tank explosion. So, while a new tank may be an upfront investment, the longer-term savings in energy efficiency, minimization of downtime, and secured safety make it an essential one.

Why Choose Advanced Air & Vacuum For Your Air Compressor Tank Replacement

With vast experience, extensive industry knowledge, and a commitment to customer satisfaction, Advanced Air & Vacuum provides premium air compressors and air compressor maintenance services designed to ensure that your industrial air compressor runs the way it should for as long as possible. We recognize that your productivity relies on the efficient operation of your air compressor, which is why we only use the highest-quality replacement tanks and parts. Through our comprehensive project consultation, we work closely with you to understand your specific needs and goals to ensure the appropriate equipment is quoted on every job.

But our services don’t stop there! We also specialize in the installation of new compressors and repair of broken air compressors. Our expert team’s careful attention can quickly and safely rectify the issue, no matter what it is. For detailed queries or professional assistance, feel free to contact us for all of your compressed air needs.