Have you ever experienced motor failure at the most inconvenient time? Of course, who hasn’t? Whether it’s in your commercial HVAC system, on the factory floor, or even at home, a malfunctioning motor can bring life to a screeching halt. Now, what if we told you that there’s a way to bring that seemingly dead motor back to life? Intriguing, right? Welcome to the world of electric motor rewinding. Electric motor rewinding is not just a revival tactic; it’s also a strategy that can save significant costs. Picture this: instead of investing a hefty sum in a brand new motor, you could restore the functionality of your current one. This approach is often quicker and certainly more cost-efficient. It’s akin to replacing the heart of the motor while preserving the body. However, not all motor repair services are created equal. Choosing a reliable and experienced company for motor rewinding can mean the difference between motor efficiency, and having a motor that merely limps along. That’s where we come in. With years of expertise in the field, our team at Advanced Air & Vacuum (AAV) is here to guide you through the world of electric motor rewinds. As we dive into the specifics of how a successful rewind can breathe new life into your motor, you’ll discover our commitment to quality, efficiency, and customer satisfaction. So, let’s switch gears and get into the details of electric motor winding.

Understanding Motor Rewinding

Let’s illuminate the somewhat mystical concept of motor rewinding. At its core, motor winding—whether it’s a phase motor or DC motor—refers to the process of replacing the copper coil or ‘motor coils’ inside the motor terminal—a coil which, when energized, forms the motor’s magnetic field and generates its power. Over time, this coil may suffer faults or thermal deterioration, necessitating a rewind.

So, why does a motor require rewinding? It could be due to several reasons: the motor could have failed due to overloaded conditions, aging, or an unfortunate voltage surge. In such cases, the internal coil winding, or ‘faulty winding’, may burn out or become damaged, compromising the motor’s performance. Thermal deterioration is also a common enemy of motor longevity. Heat can degrade the insulation around the wire winding, leading to internal short circuits. In each of these scenarios, a motor rewind or electric motor repair can rectify the issue, effectively giving your motor a new lease on life.

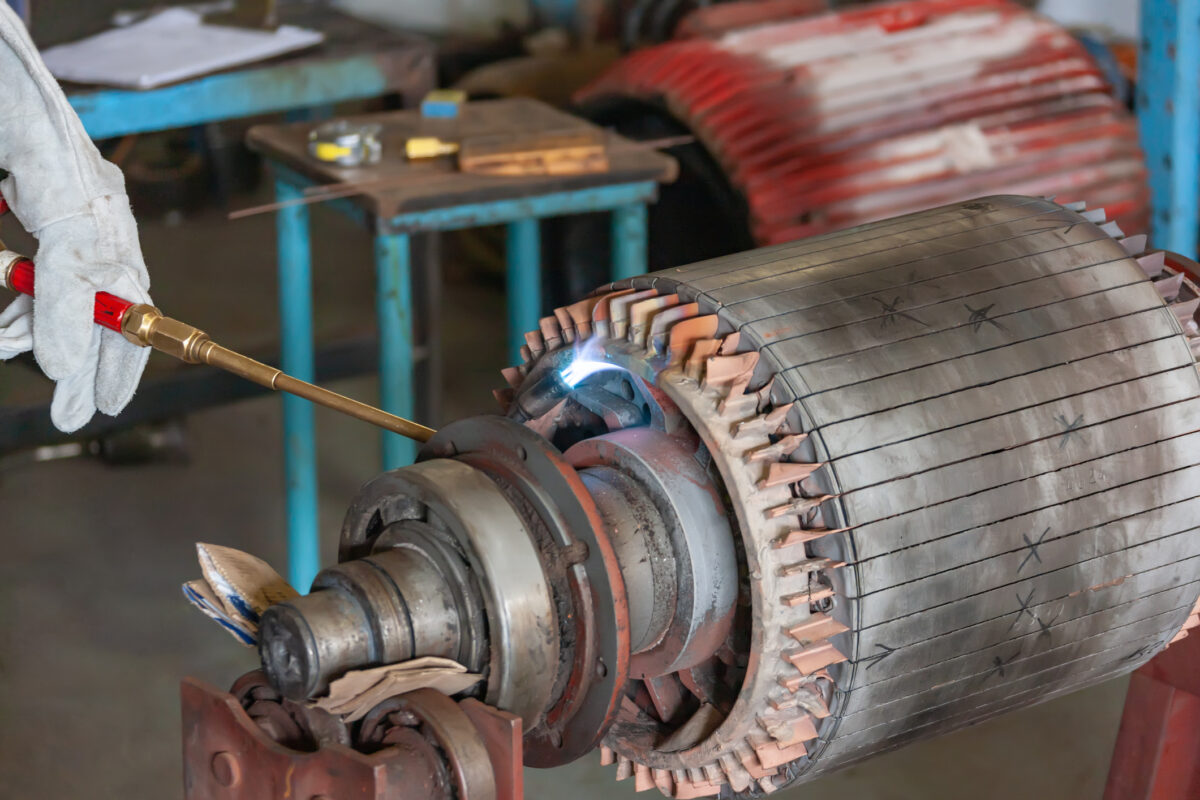

Diving into the nitty-gritty of the process, the motor rewind involves several key components: the core material or ‘stator core’, insulation resistance, and the magnetic field, which is a critical component. First, the old, damaged coil is carefully removed, and the stator core is inspected and repaired if necessary. A ‘new winding’ is then wound onto the core, and high-quality insulation is applied to resist heat and prevent electrical failures. The focus is to maintain the motor’s original magnetic field characteristics, ensuring its performance, even at a higher speed, is not diminished after the rewind. With variable frequency drive, this might sound straightforward, it requires a keen understanding of the motor’s specifications and meticulous execution.

Best practices in motor rewinding involve the correct selection of wire gauge, precise winding techniques, and the use of high-quality insulation material. All these steps play a crucial role in ensuring the rewound motor works efficiently and maintains its longevity. This is why the skills of the repair technician are paramount. An experienced technician understands the intricate details of motor design and can perform the rewind to meet, or even exceed, original equipment manufacturer (OEM) specifications. In the next section, we will explore the tangible benefits that come with choosing motor rewinding over buying a new one. Stay tuned!

Benefits of Electric Motor Rewinding

Now that we have unveiled the mechanics behind electrical motor rewinding, let’s switch our focus to its array of benefits. Opting for motor rewinding, instead of purchasing a new one, presents a multitude of advantages, chief among them being significant cost savings. A rewind is typically a fraction of the cost of a new motor. Just think of it in terms of a heart transplant – it’s far more cost-effective to replace the heart than the entire body. The same principle applies here. By replacing only the damaged winding head or the ‘faulty winding’ and leaving the motor body intact, you are effectively saving on the costs associated with manufacturing and installing a completely new motor. But the benefits aren’t purely financial.

Motor rewinding also makes a substantial contribution towards environmental sustainability. In a world where reducing carbon emissions and waste is a top priority, motor rewinding offers an eco-friendlier option than replacing the entire motor. When you choose to rewind, you’re saving the bulk of the motor from landing in a landfill. Additionally, the energy consumed in producing a new motor far exceeds that used in the rewinding process. A rewind can also preserve the unique qualities of your motor. Many motors in service today are older models, built with a level of craftsmanship and materials that simply can’t be replicated with modern manufacturing techniques. In such cases, a rewind allows you to maintain the motor’s original robustness and reliability. It’s essential, however, to remember that the success of a rewind largely depends on the skills of the repair technician and the quality of the materials used. Remember, unequal voltage and temperature can affect the performance of a ‘permanent magnet’ motor. In the next section, we’ll introduce you to a team that guarantees quality rewinds – the experts at Advanced Air & Vacuum.

The Advanced Air & Vacuum Advantage

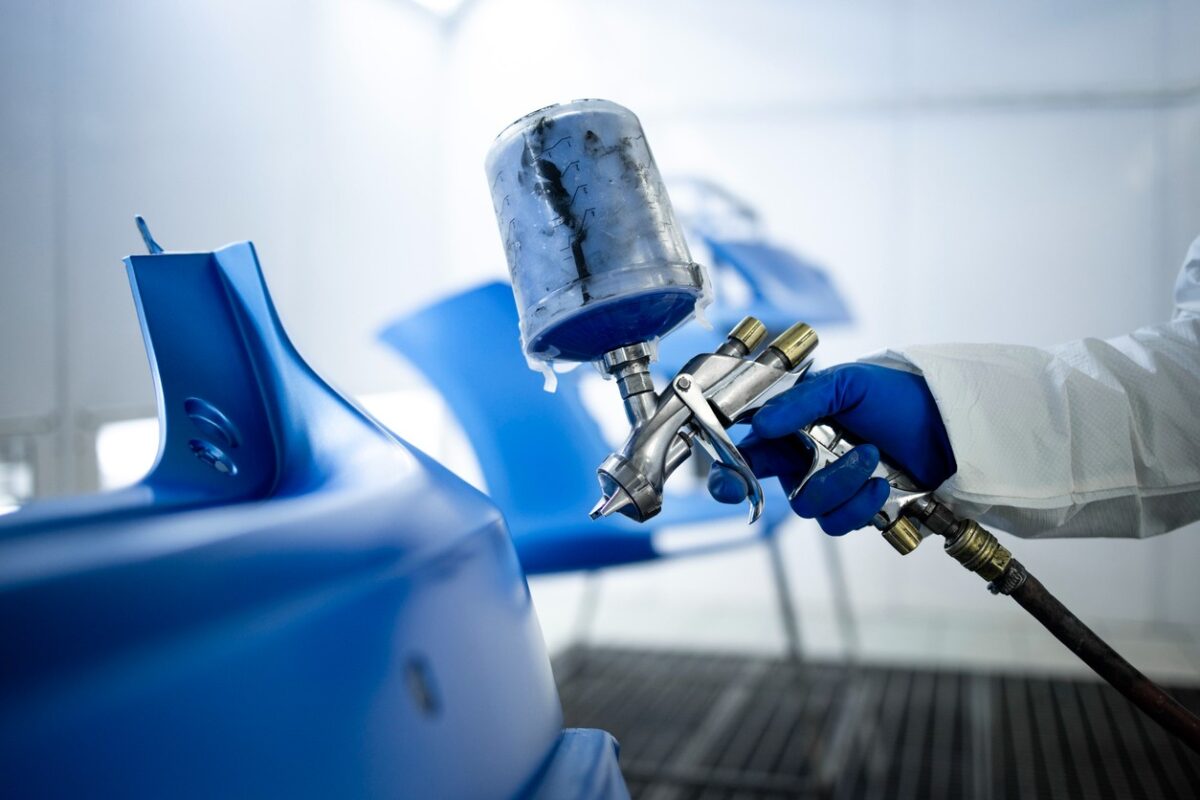

When it comes to motor rewinding, Advanced Air & Vacuum (AAV) stands as a beacon of excellence and reliability. As specialists in motor repairs and services, we’re committed to providing superior service, high-quality materials, and expert craftsmanship that ensures your rewound motor runs smoothly and efficiently. AAV is not just any service center; we’re a team of dedicated experts specializing in air compressors, vacuum pumps, and, of course, motor rewinding.

With years of experience under our belts, we’ve fine-tuned our skills to tackle any repair or rewind job, big or small, simple or complex. But what really sets us apart is our authorized service center status for leading brands. This stamp of approval not only represents the trust placed in us by industry giants, but it also reflects our commitment to staying current with the latest industry trends and technical advancements. Our technicians are regularly trained and updated with the latest practices, ensuring that every motor rewind meets or surpasses original equipment manufacturer (OEM) standards.

Our focus extends beyond just providing a service; we’re also committed to customer education and satisfaction. We believe in transparent communication and keeping our customers informed at every stage of the process. It’s part of our goal to build strong, long-term relationships based on trust, integrity, and mutual respect. So, if you’re in need of motor repair services, and particularly motor rewinding, remember that AAV is ready and equipped to offer superior service. In the next section, we’ll wrap up the discussion and outline the steps to take if you decide to give your motor a new lease on life through rewinding.

Electric motor rewinding is a smart, cost-effective, and sustainable solution for dealing with motor failures or deteriorations. It breathes new life into your motor, preserving its unique qualities, and reducing waste. However, the success of a motor rewind largely hinges on the skills of the technician and the quality of the materials used.

This is where Advanced Air & Vacuum steps in. As a trusted and authorized service center for many leading brands, our expertise in motor rewinding is unrivaled. We’re not just here to offer a service; we’re committed to providing a superior customer experience, characterized by transparency, education, and satisfaction. Don’t let a malfunctioning motor slow you down. Whether it’s an air compressor, vacuum pump, or another type of motor, reach out to us at AAV. Our team of experienced professionals is ready to give your motor a new lease on life. Contact AAV today for more information!